Explore Our Comprehensive Services

Cable Tray

The installation and maintenance of cable trays are vital for ensuring organized wiring and enhancing safety in electrical systems. Cable trays provide structured support for various cables, minimizing the risk of damage and facilitating efficient routing. During installation, careful planning is essential to determine the appropriate type and size of the tray, ensuring it can support the load. Proper mounting techniques are used to secure the trays to walls or ceilings, followed by the organized placement of cables to prevent overheating and ensure accessibility for future maintenance. Regular inspections and cleaning of cable trays help identify wear or debris buildup, promoting fire safety and compliance with electrical codes. By maintaining an orderly setup, cable trays allow for easier troubleshooting and contribute significantly to the overall safety and efficiency of electrical installations.

HVAC Installation

The complete setup of an HVAC system encompasses various critical components, including ductwork and chiller installation. Proper installation begins with assessing the building’s heating and cooling needs to determine the appropriate size and type of HVAC equipment. Ductwork is then designed and installed to efficiently distribute conditioned air throughout the space, minimizing energy loss. This includes determining the optimal layout to enhance airflow while ensuring easy access for maintenance. The chiller, a key component in larger systems, is installed to provide cooling, typically through a refrigerant cycle. Regular maintenance of both the ductwork and chiller is essential to ensure optimal performance, improve energy efficiency, and prolong the lifespan of the system. A well-designed HVAC system contributes significantly to indoor air quality and comfort, making professional installation and upkeep vital for any commercial or residential building.

Motor & Machinery Repairs

Professional rewinding and repair services for motors and industrial machinery are essential for maintaining operational efficiency and minimizing downtime. This process involves carefully disassembling the motor to assess damage, often caused by wear and tear, overheating, or electrical faults. The stator and rotor windings are meticulously inspected, and if necessary, old wire is removed and replaced with high-quality, durable material. Additionally, bearings, seals, and insulation are checked and replaced as needed to restore the motor's functionality. Properly executed rewinding not only extends the life of the equipment but also enhances performance, ensuring that machinery runs smoothly and reliably. Regular maintenance and prompt repairs can save businesses significant costs in replacement parts and lost production time.

Boiler Services

Expert boiler repairs and maintenance services are vital for ensuring the safety, efficiency, and longevity of boiler systems. These services typically involve routine inspections, cleaning, and repairs to prevent breakdowns and ensure optimal performance. Technicians assess the boiler's components, such as burners, heat exchangers, and controls, to identify issues that could affect efficiency or safety. Common maintenance tasks include descaling, checking pressure levels, replacing faulty parts, and ensuring that safety valves are functioning correctly. Regular maintenance not only extends the life of the boiler but also reduces energy costs and minimizes the risk of catastrophic failures, ensuring reliable heating and hot water supply in residential and industrial settings.

Generator Services

Repair and maintenance of generators are crucial for ensuring their smooth operation and longevity. Regular maintenance involves checking fuel systems, oil levels, and cooling systems to prevent failures and extend the generator's lifespan. Technicians conduct routine inspections to identify wear and tear, replace filters, and perform necessary repairs on components such as alternators and voltage regulators. Keeping generators in optimal condition minimizes the risk of unexpected breakdowns, ensuring they function effectively during power outages or peak demand periods. Routine servicing can also enhance fuel efficiency and reduce emissions, contributing to more environmentally friendly operations.

Lighting Installation

Installation and maintenance of street lighting systems are essential for ensuring public safety and enhancing urban aesthetics. This process involves setting up light poles, fixtures, and wiring to provide adequate illumination on streets, sidewalks, and public areas. Proper installation ensures that the lights are strategically placed to maximize visibility and minimize light pollution. Regular maintenance includes inspecting and replacing faulty bulbs, checking electrical connections, and ensuring that light fixtures are clean and free from obstructions. This proactive approach helps in identifying issues before they become significant problems, thereby reducing downtime and improving energy efficiency. Well-maintained street lighting not only enhances safety but also deters crime and supports community engagement by making public spaces more inviting.

Fabrication Machinery

Repairing and overhauling various fabrication machinery involves a comprehensive approach to restore and enhance the functionality of equipment used in manufacturing processes. This service includes inspecting machinery for wear and tear, diagnosing mechanical issues, and performing necessary repairs such as replacing worn-out parts and recalibrating systems to meet operational standards. Overhauls may also entail complete disassembly and refurbishment of machines, ensuring that all components are in optimal working condition. Regular maintenance checks help in prolonging the lifespan of fabrication machinery, minimizing unexpected breakdowns, and improving productivity in manufacturing operations. This expertise is crucial in industries where precision and efficiency are vital to success.

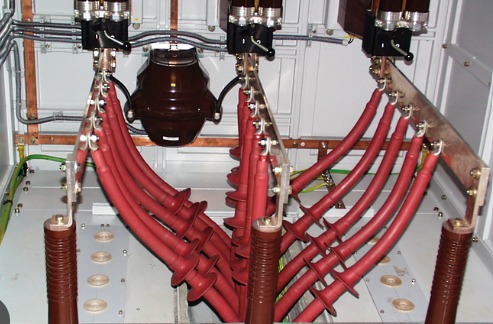

Electrical Motor Control Panels

We offer specialized services for electrical motor control panels, including installation, testing, and commissioning. Our team ensures that your control panels are wired correctly and meet safety and operational standards. We provide in-depth troubleshooting for issues such as faulty connections, short circuits, or malfunctioning relays and contactors. Our services extend to cabling, panel layout optimization, and testing under load conditions to ensure your control panels perform reliably in various operational environments. Whether you need new installations or upgrades for existing systems, we have the expertise to deliver high-quality, safe, and efficient solutions.

Fire Fighting Pump

Fire fighting pumps are essential components in fire protection systems, designed to provide a reliable source of water for extinguishing fires. These pumps can draw water from various sources, such as tanks, lakes, or hydrants, ensuring that firefighters have adequate pressure and flow to combat fires effectively. Installation involves careful consideration of the pump's capacity, type (such as centrifugal or positive displacement), and the layout of the piping system. Regular maintenance is crucial for fire fighting pumps to ensure they operate effectively in emergencies. This includes routine inspections, testing the pump's performance, and replacing worn components to prevent failures during critical situations. A well-maintained fire fighting pump system enhances the overall safety and readiness of a facility, contributing significantly to fire safety management.

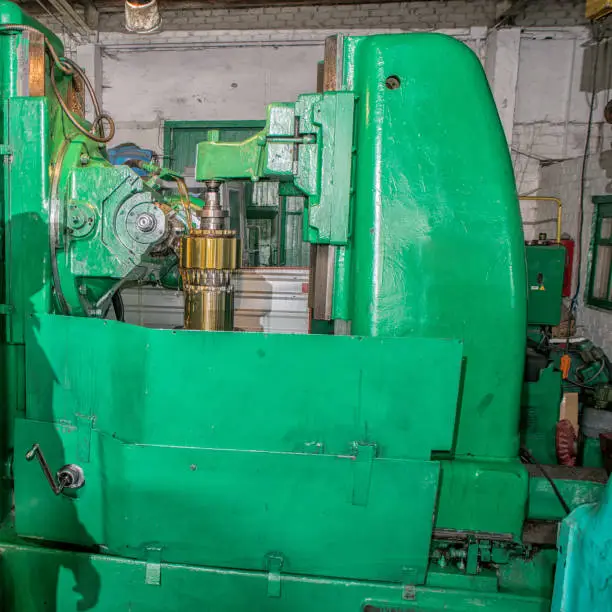

Milling Machine

Our expertise in milling machines includes the maintenance, repair, and troubleshooting of various components, such as lathe machines, banding machines, rolling machines, and shearing machines. We specialize in identifying mechanical issues like improper alignment, worn-out tools, or electrical malfunctions that can slow down production. We offer services that not only ensure immediate repair but also provide routine maintenance to prevent future breakdowns. With a focus on improving machine accuracy and reducing vibrations, we help your production floor remain efficient, reducing production delays and improving the quality of your final products. Our team provides fast response times and reliable service, ensuring minimal disruption to your operations.

Air Compressor Services

Complete overhauling and repair of air compressors and their control systems is crucial for ensuring efficient and reliable operation in various applications. This service typically involves a thorough inspection to identify any wear or damage in the compressor components. Key tasks may include replacing filters, seals, and gaskets, as well as checking and adjusting the pressure settings to ensure optimal performance. addition to mechanical repairs, attention is also given to the control systems, which manage the compressor's operation. This can involve recalibrating control settings, updating software, and ensuring all electronic components are functioning correctly. Regular maintenance and overhauls help prevent unexpected breakdowns, extend the lifespan of the equipment, and maintain energy efficiency, which is essential for reducing operational costs. For more information, you can check out resources that discuss air compressor maintenance and overhauling techniques.

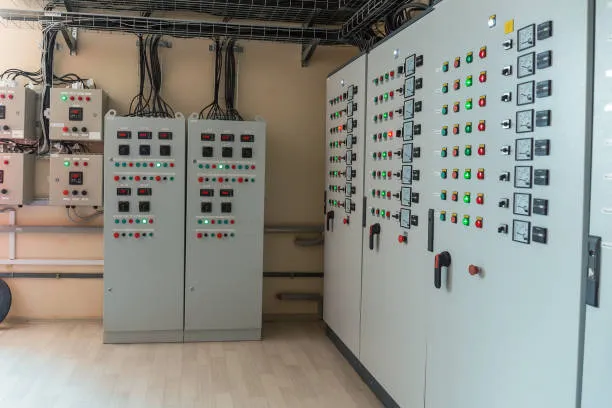

Electrical Installation of Panels

Our electrical installation services for panels encompass a comprehensive approach to setting up control panels, distribution boards, and other electrical systems. We specialize in ensuring that all components are installed according to the latest safety regulations and operational standards. Our team conducts thorough inspections and testing after installation to guarantee optimal functionality and reliability. This includes: Custom design of panel layouts to meet specific operational needs. We utilize high-quality materials for long-lasting installations and conduct rigorous testing of all electrical connections to ensure safety and performance. Our services adhere to local and national electrical codes to mitigate risks, and we provide ongoing support and maintenance to address any issues promptly. Our commitment is to deliver safe, efficient, and reliable electrical systems that enhance your operational capabilities.